Applying Carlisle HVAC Brands’ Sealants and Coatings

Applying Carlisle HVAC Brands’ Sealants and Coatings

Liquid Duct Sealants and Coatings

Liquid Duct Sealants and Coatings come in either a water-based or solvent-based formula.

Water-based formulas are the most popular due to their physical properties which allow for ease of application, less odor in the wet state, minimized environmental impact, indoor air quality focus, and offer multiple application methods.

Solvent-based formulas are popular where limited time is allowed for curing and have fewer application methods due to their physical properties.

Rolled (Tape) Mastic Sealants

Rolled (Tape) Mastic Sealants are a 100% solids product that are fully cured when manufactured Rolled Mastic Sealants are popular for ease and cleanliness of application and the ability to immediately test the HVAC system once sealed

Application Tools

Mil Tool

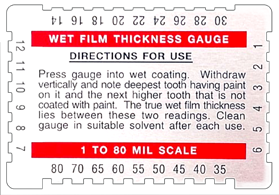

When it comes to the application tools there are several options to fit any job. Mil gauge – the most important tool. A mil gauge is used to verify the appropriate application thickness. You press it into the product, pull straight back off the surface, then check which tooth has product and the next closest tooth that has no product on it. Split the difference and you can read the mil thickness off the side of the gauge. Our goal in the end is to have a minimum specified amount of wet mils over the joints and seams for the appropriate sealing efficacy. We have included a small chart below to show the recommended application thickness by product type.

When it comes to the application tools there are several options to fit any job. Mil gauge – the most important tool. A mil gauge is used to verify the appropriate application thickness. You press it into the product, pull straight back off the surface, then check which tooth has product and the next closest tooth that has no product on it. Split the difference and you can read the mil thickness off the side of the gauge. Our goal in the end is to have a minimum specified amount of wet mils over the joints and seams for the appropriate sealing efficacy. We have included a small chart below to show the recommended application thickness by product type.

Application Thickness By Product Type |

||

| Product | Application Method | Application Thickness |

| Liquid Sealants |

Bucket & Brush Spray Applied Cartridges |

20 to 30 wet mils 20 to 30 wet mils Bead that completely covers joint |

| Coatings |

Bucket & Brush Spray Applied |

15 to 20 wet mils 16 to 20 wet mils |

Brush

Brush

When applying sealant via the bucket & brush method, the correct style of brush makes application easier and more consistent. The appropriate brush is called a “chip brush”. A chip brush utilizes natural fibers set into a wooden handle. The natural fiber bristles are shorter and stiffer than a standard paint brush. These brushes are considered a single-use item. Brush width is typically 2" or 3" wide for bucket & brush applications.

Caulking Tubes

Caulking Tubes

Caulking tubes are simple, requiring the use of an appropriate cartridge gun (12 oz caulking gun) and a knife to cut the tip of the cartridge. The depth of the cut will set your bead width. Care should be taken to cut the cartridge tip slightly larger than the size of the joint you are sealing. Most cartridge guns offer a tip cutter built into the handle and include a puncture wire located on the underside of the barrel. Care must be taken to puncture the seal effectively to allow the sealant to properly exit the cartridge.

When utilizing cartridges, it is recommended to use a caulking tool to finish detailing the sealant and get a consistent seal. When tooling the sealant do not use bare hands or fingers due to the potential cut hazard.

Airless Sprayer

Airless Sprayer

When utilizing spray-applied sealants and coatings it is key to use the appropriate style spray pump. Water-based liquid sealants and coatings have fairly high viscosities that require the power of a piston-style pump to move the product and supply the higher pressures needed to atomize and spray the products. Gravity-feed style or diaphragm-style pumps are not recommended as they are limited in the maximum air pressure available to move and atomize the product as required.

What pressure setting should I use for the sealants and coatings? Piston-style pumps deliver pressures up to 3300 PSI. We recommend starting in the 1500 to 1600 PSI range and then adjusting up or down to get the full spray pattern needed for the best coverage.

Plastic Squeegee

Plastic Squeegee

Use the Hardcast squeegee for smoothing out wrinkles and bubbles that might form in the application of the rolled mastic sealant. Use positive pressure to ensure a flat surface and maximum adhesion to eliminate air leakage coming in or out of the transverse joints and longitudinal seams. The flexibility of the squeegee will allow the rolled mastic sealant to conform to angle changes and penetrations into joints and seams. The Hardcast squeegee has a twin rib design for easy handling and pressure control.

What issues can you run into if you over or under applying Liquid product?

It is key to understand, how the sealants and coatings cure. Water-based products cure from the outside in, so the surface starts curing first and then the remaining water evaporates from underneath through the cured film. Solvent-based products cure in the same fashion, but the use of solvents allows the product to cure faster as the solvent will evaporate at a highly accelerated rate compared to water.

Too Thick

Too Thick

- Extended Drying Times: Over-applying sealant/coating will lead to Extended Drying Times. There is also more product to cure through. In addition, it can extend off-gassing and “smell” while the product cures through.

- Possible Mud Cracking: Liquid duct sealants are not a 100%-solids product. They are typically in the range of 60% to 75% solids content. Coatings are typically in the range of 50% to 60% solids content. This means these products will slightly shrink when curing. When over-applying, the excess product can cause additional shrinking which can crack and/or tear the cured film. This appears as mud-cracking.

- Tip: Angle Changes: It is easy to over-apply on angle changes as you are traversing over an edge, applying into a corner, etc. Watch these areas closely when applying and adjust your application as needed. You can always tool the joint, seam, or corner to remove the excess.

Too Thin

- Under-applying sealant/coating will lead to the sealant/coating dries too thin. This leaves an improperly sealed/coated application.

- Loses elastomeric and UV properties. Improperly sealed/coated application will impact residual flexibility, potentially allowing the product to crack. Improperly sealed/coated application can be vulnerable to UV.

- The product won’t seal/coat.

- Tip: Angle Changes: It is easy to over adjust when re-working over an edge or in a corner. Watch these areas closely when applying and adjust your application as needed. You can always add to the joint, seam, or corner to get to the appropriate mil thickness.

Overworking

- Overworking and or continuing to brush (overwork) the sealant/coating will lead to thinning out the application below the minimum recommended mil thickness. This can lead to the issues addressed above. Continuing to brush (overwork) will also cause hills and valleys due to the brush strokes, which will cause areas to be applied too thin.

- Loses elastomeric and UV properties. Improperly sealed/coated application will impact residual flexibility, potentially allowing the product to crack. Improperly sealed/coated application can be vulnerable to UV.

- The product won’t seal/coat.

General Application Tips

Ensure the proper surface preparation is done and understand how the temperature and humidity can impact your installation. Properly prepare the surface by making sure it is: Dry, Dirt free, Oil/grease free. If oil/grease is present, it is recommended to wipe down the surface with a solvent that is acceptable in the jurisdiction where the sealant/coating is being applied.

Cure time will be impacted by temperature and humidity levels.

- Cure time will be extended in lower temperature application conditions. Apply products when temperatures will not fall below freezing for 36–48 hours.

- Cure time will be extended in high-humidity application conditions. Apply products when there is no rain forecasted for 36–48 hours.

- Temperature and humidity after the install is just as important.

- Make sure you are applying the product within the application temperature range. Water-based sealants/coatings are 35°F to 110°F. Solvent-based sealants/coatings are 25°F to 100°F.

- Don’t confuse the service temperature range for application temperatures. All sealants/coatings are -20°F to 200°F.

Request More Information

Please complete the form and a member of our team will reach out to you.