Why Hardcast’s Liquid Sealants Are Superior For Ductwork

Why Hardcast’s Liquid Sealants Are Superior For Ductwork

We explain the minimum requirements that HVAC liquid sealants must meet and will describe the additional testing and listing that Hardcast performs to give you the best product on the market.

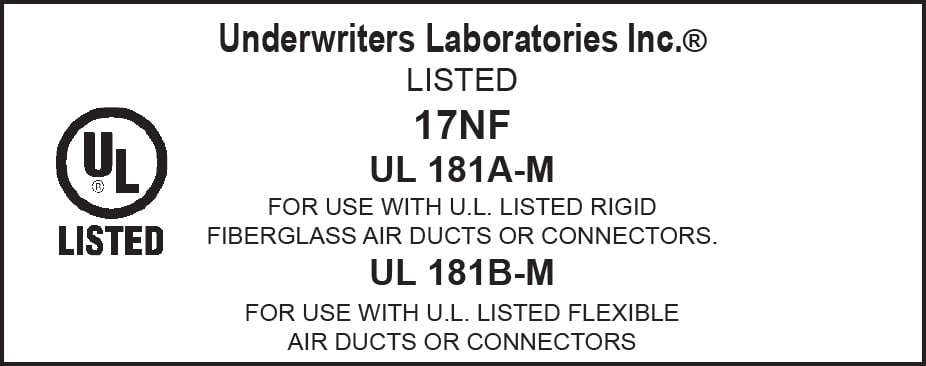

The minimum requirement for a UL Listed HVAC duct sealant/mastic is UL Standard UL 181. If the product shows the UL logo followed by “Listed”, then you know the product has been tested by UL (or a third party) to the UL 181 standard. Other UL 181 labeling options exist, such as “Recognized”, “manufactured in conformance with”, etc. Products that are “Recognized” might pass most, but not all of the required testing for the UL Listing. Kind of an “almost, but not quite there” product. Products showing “in conformance with” or similar language typically have not been tested or reviewed by UL or a third party, so there is no guarantee that the product will perform.

Let’s break down what UL 181 covers, as there are many sub-set items within the standard.

- UL 181 – Standard for Factory-Made Air Ducts and Air Connectors

- UL 181A – Standard for Closure Systems for Use With Rigid Air Ducts

- UL 181B – Standard for Closure Systems for Use With Flexible Air Ducts and Air Connectors

- UL 181A-M – Mastic Closure Systems for Use With Rigid Fiberglass Air Ducts

- UL 181B-M – Mastic Closure Systems for Use With Flexible Air Ducts

- UL 181B-FX – Pressure-Sensitive Tapes for Use With Flexible Air Ducts

- UL181A-P – Pressure-Sensitive Aluminum Tapes for Use With Rigid Fiberglass Air Ducts

Look for the official UL symbol on the product. Without this the product is not UL approved and is subject to fines and removal from the job site. Now let’s look at the actual tests a product must go through to get an approved UL 181 Listing. UL 181 involves testing for the following parameters:

- Surface Burning Characteristics

- Burn Test

- Mold Growth and Humidity

- Temperature Test

- Pressure Test

- Shear Adhesion

- Tensile Joint Strength

- Peel Adhesion

The Surface Burning Characteristics and Burn tests are done in accordance with UL 723. To pass the test successfully, the product must have:

- A fame-spread rating of not over 25 without evidence of continued progressive combustion, and

- A smoke-developed rating of not over 50 when applied to inorganic reinforced cement board.

The Mold Growth and Humidity tests require that the products shall be resistant to the effects of high humidity under ordinary atmospheric temperature conditions. Three samples are prepared which go through the following steps:

- Mold mycelia and spores from Chaetomium Globosium are to be applied to both sides of the specimens. The specimens are to be placed in a closed vessel in which an atmosphere saturated with water vapor is maintained at room temperature under dark conditions. The specimens are to remain in this atmosphere until the maximum extent of growth has been demonstrated, or until the mold and spores have disintegrated, but not less than 60 days.

- The specimens then are to be examined visually for extent of mold and for indications of deterioration of the tape specimens. The mold shall not have spread beyond the inoculated area, and no signif cant growth of mold shall be observed.

The Temperature test requires that the product shall be resistant to the effects of the high temperature conditions to which it is exposed during this test. Twelve specimens are created and placed in an air-circulating oven maintained at 212 ±5°F (100 ±3°C) for a period of 60 days. The samples are then examined visually for indications of deterioration, brittleness, cracking, faking, and blistering.

The Tensile Strength test requires the products to have a tensile strength of no less than 25 pounds per inch. The Peel Adhesion test requires the products to have a peel strength from the substrate of no less than 3.75 pounds per inch. The Shear Adhesion test requires the products to have a shear strength able to hold the weight of test specimens in either 5 or 10 pounds for anywhere from 6 to 120 hours. These three tests are used to show that the product will remain in place and will seal against the pressure in the duct system, as well as make sure the joint, seam, or closure remains air-tight.

Hardcast’s additional testing, above and beyond minimum requirements

Hardcast’s additional testing, above and beyond minimum requirements

After examining the basic requirements to receive the UL 181 Listing, you can see it is pretty challenging. But at Hardcast, we do not stop there; we perform testing above and beyond the minimum requirements. Why? When you are talking to a customer, whether that be over the phone or on a jobsite, you need to have all information available to you to answer any question that may arise and show that Hardcast is the superior company for sealing ductwork. Hardcast’s Technical Data Sheets detail the additional testing we perform and certifications we have received. A small list is below:

UL’s GreenGuard and GreenGuard Gold Certifications

“UL Environment’s GREENGUARD Certification program helps manufacturers create--and helps buyers identify and trust--interior products and materials that have low chemical emissions, improving the quality of the air in which the products are used. All certified products must meet stringent emissions standards based on established chemical exposure criteria.”

The Certifcation program has two levels for low-emitting products. Those are defined below with the appropriate product label that denotes the certification.

“The GREENGUARD Certification Program (formerly known as GREENGUARD Indoor Air Quality Certification) gives assurance that products designed for use in indoor spaces meet strict chemical emissions limits, which contribute to the creation of healthier interiors. Achieving GREENGUARD Certification gives credence to manufacturers’ sustainability claims, backing them with empirical scientific data from an unbiased, third-party organization” (reference 3).

“GREENGUARD Gold Certification (formerly known as GREENGUARD Children & Schools Certification) offers stricter certification criteria, considers safety factors to account for sensitive individuals (such as children and the elderly), and ensures that a product is acceptable for use in environments such as schools and healthcare facilities. It is referenced by both The Collaborative for High Performance Schools (CHPS) and the Leadership in Energy and Environmental Design (LEED) Building Rating System” (reference 4).

The Hardcast line of water-based duct sealants/mastics have been awarded UL GREENGUARD and UL GREENGUARD Gold Certifications. These products will help specifiers meet the requirements on the numerous green building and design programs and building codes. These include LEED, GSA Advantage, the Collaborative for High Performance Schools (CHPS), the International Green Construction Code (IGCC), and European Union guidelines and directives.

GreenGuard Certified products meet stringent chemical emission requirements, such as being screened for more than 10,000 volatile organic compounds (VOC’s). Products undergo routine monitoring and annual testing to maintain this certification. The comprehensive science, vigorous certification requirements, and third-party status that back the GreenGuard certification program will differentiate these certified products in the market place.

EPA/USDA/FDA approval for use within food preparation areas

EPA/USDA/FDA approval for use within food preparation areas

Products that don’t have NSF Certification will typically have EPA/ USDA/FDA approval. Once again, the inherent safety this registration gives to the end user is crucial.

Food Safety and Inspection Services (FSIS) approval for use in construction of federally inspected meat and poultry plants

Some products have been through more specific approvals so they can be used in meat and poultry plants.

Durability testing per Hardcast test method RA 14.0

This test places the products in a positive pressure situation over hole sizes which are substantially larger than what is typically seen in the feld. Samples are created by drawing down 20 wet mils of product over 1/8", 1/4", 3/8", and 1/2" holes and letting it dry for 24 hours. These samples are then placed on pressure testing equipment where the equipment is set to above 20" of w.g. and run for 15 minutes. Keys to this test are the thinner application rate and the fact that the pressure is brought to the maximum setting immediately upon the start of the test. This is a big stress test, and all products must pass to bear the Hardcast name.

South Coast Air Quality Management District (SCAQMD) – verification of low-VOC product per rule 1168

The SCAQMD has strict regulations, which is a great example for all areas. Per rule 1168, products must have no more than the maximum of 250 grams per liter of volatile organic compounds (VOCs), less water and less exempt compounds, to be considered a low-VOC product. Hardcast products are well under this maximum. The exempt compounds are something to pay attention to, as these can be used to the manufacturer’s advantage to claim a low to zero-VOC product.

City of Los Angeles Approval – Approval RR 8069

This approval allows the use of the Hardcast liquid sealants on commercial and residential buildings in the greater Los Angeles area.

US Coast Guard (Department of Homeland Security) Interior Finishes 46 CFR 164.012

This approval tests products for fame spread and smoke developed, as discussed earlier in this document. However, for products being used on vessels in open water, the fame and smoke must pass 20/10 respectively above the standard 25/50 requirement. This testing shows Hardcast products are well under the standard maximum.

To round out the additional testing, Hardcast liquid sealants will pass fve freeze/thaw cycles. This means you can freeze the product solid and thaw it back out fve times before the product becomes unusable. This is highly important during the winter months in cold-climate areas. In addition, several products have passed testing to verify low-temperature flexibility and low-temperature crack bridging. Once again, these properties are highly important in cold-climate areas.

Every single batch of liquid sealant product manufactured in our facilities is quality tested prior to shipping. In this quality testing, we verify the viscosity, pH level, and flexibility of the product. The flexibility test consists of applying the product at 30 wet mils to a 4" x 4" piece of galvanized metal. This is allowed to be fully cured. Once cured, the sample is literally folded over on itself. This tests the peel strength, shear strength, and tensile strength, and makes sure the product will flex with the deformation of the sample metal. Most importantly, if you were ever to have an issue with a product, we can test that product in our facility. We keep a sample of every batch for a minimum of one year from the date of manufacture.

CTM RA14.0 Pressure testing of all liquid sealants above 20" of w.g. All liquid sealants must pass to bear the Hardcast name.

Sealant, “pookie”, duct butter, mastic, or whatever name is used in your local area gives the impression that these liquid sealant products are simply commoditized sealants. However, with more states adopting stricter energy codes regarding duct sealing and testing, it is prudent to go with a company that can provide the maximum capabilities in sealing ductwork. Hardcast liquid sealant products are truly engineered duct sealants from an industry leader with over 50 years of knowledge and experience, so go with the BEST and go with Hardcast.

Request More Information

Please complete the form and a member of our team will reach out to you.